Glass Exhibits

Ongoing Glass Exhibits

The museum’s collection reflects the broad range of glass produced by Christian Dorflinger’s companies from 1852-1921. A highlight of any tour is the Dorflinger Timeline—three display cases in which glass is arranged chronologically from the earliest examples of Dorflinger glass (made in the 1850s) through glass made near the end of the factory’s production. Printed guides to the exhibit give detailed information about many items and discuss the history of the company allowing visitors to take a self-guided tour at their own pace.

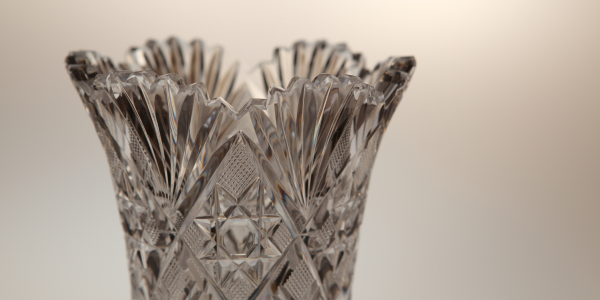

Visitors see firsthand the differences in Dorflinger glass through the decades. The earliest examples are relatively simple patterns cut with only a few motifs. The middle case illustrates the peak production period of the company when it was best known for a richly cut (brilliant) series of deep cutting in ornate, geometric patterns. The later glass reflects the change in popular taste after the beginning of the 20th century when lighter cutting and etching took place creating more floral designs.

In addition to the timeline, displays show glass on long-term loan from several descendants of Christian Dorflinger. This family glass has many examples of historic glass and several important pieces that belonged to Christian Dorflinger and members of his immediate family.

One display case is dedicated to examples of Presidential glass and also items made on order to the Tiffany silver company for the wedding of William Vanderbilt to Virginia Fair.

The first Dorflinger glass for the White House was ordered by Mary Todd Lincoln. In 1891, a new Dorflinger design was selected by Caroline Harrison, wife of President Benjamin Harrison. Dorflinger glass was ordered for the White House through the presidency of Woodrow Wilson.

The Vanderbilt piece was designed by Tiffany’s in New York, who subcontracted the blowing and cutting of the glass to Dorflinger in White Mills. All the pieces had elaborate silver holders and were done in either green or red glass, lightly cut in a rock crystal floral pattern.

The Walter and Marilyn Barbe Wayne County Glass Gallery

The Walter and Marilyn Barbe Wayne County Glass Gallery is located just past the first room of the gift shop in the original section of the Christian Dorflinger home. Wayne County had over 70 glass manufacturers and cutting and decorating shops, of which more than 30 are represented.

A large dark olive colored carboy (a large bottle used for holding corrosive liquids) made at the second glass factory in Wayne County outside of Bethany (1816-1848) and a bottle and basket from Honesdale Glass Works (1846-61; 1873-97) represent the earliest of the three area factories. Only a framed shard of glass represents the Rockville (1807-1819) factory site where windowpanes were being made by the cylinder method and being shipped to Philadelphia.

The shelves in one case show the steps in cutting glass, a technique introduce into the county by Dorflinger in 1867. An example of a plain blank, the first step of this process is followed by the blank marked in red lead for the cutter to lay over the pattern. The next shelf shows an example of a piece rough cut with an iron wheel, the first stage of the cutting process. The smoother then fills in the more intricate lines. The final step is polishing of the glass, earlier with a wooden wheel or brush and later by acid dipping. Examples of hand polishing and acid dipping are seen throughout the gallery.

Factories Represented in the Gallery

- Clinton Cut Glass Company (1904-1917)

- Enterprise Cut Glass Company (1904-1906)

- Feeney & McKanna, and McKanna Cut Glass Company (1906-1928)

- Hatch & Clark, T. B. Clark (1884-1927)

- Herbeck-Demer Cut Glass Company (1906-1910)

- Honesdale Cut Glass Company (1902-1906)

- Irving Cut Glass (1900-1933)

- J. S. O’Connor (1890-1902).

- Kelly & Steinman (1895-1912)

- Keltz-Myers, Frank J. Myers & Son (1906-1910)

- Keystone Cut Glass Company (1902-1918)

- Krantz & Smith, Krantz & Sell, G. Sell & Co. (1898-1932)

- Maple City (1898-1911)

Many of these were cutting shops that bought uncut, blown glass blanks from Dorflinger and then cut their own patterns on them. This can make identifying the factory difficult. Several of these cutting shops managed to survive into the early 1930s.